Why does a bottle of generic ibuprofen cost $2 while the brand-name version costs $15? It’s not magic. It’s math. And the math behind generic drug production tells a clear story: generic drugs are cheaper because they avoid the massive expenses that branded drugs carry - not because they’re lower quality, but because they don’t have to pay for the same things.

No R&D, No Billions

Branded drugs take 10 to 15 years and about $2.6 billion to develop. That money goes into testing, clinical trials, safety studies, and proving the drug works in real patients. Generic manufacturers don’t do any of that. Instead, they only need to prove their version works the same way - a process called bioequivalence. That’s it. No new science. No new patents. Just a lab test showing the active ingredient behaves identically in the body. The result? Generic development costs drop from $2.6 billion to between $2 million and $5 million. That’s a 99% reduction in upfront investment. That savings doesn’t disappear - it flows straight into lower prices for patients and insurers.Scale Is Everything

Once a generic drug hits the market, it’s not just one company making it. Dozens might. When six or more generic makers produce the same drug, prices can drop over 95% compared to the original brand. Even with just two competitors, generic prices are already 54% lower than the branded version. Why? Because of volume. Every time production doubles, unit costs fall by 18%. If a company makes 10 million pills, each pill costs a certain amount. Make 20 million? Each pill costs less. Make 40 million? Even less. This isn’t theory - it’s a proven trend from Boston Consulting Group’s analysis of 15 major generic manufacturers. The more you make, the cheaper each unit becomes. That’s why companies like Teva and Sandoz dominate the market. They produce billions of pills a year. Their factories run nonstop. Their supply chains are optimized. Their overhead is spread across millions of units. Smaller players can’t compete unless they hit that scale - and many don’t survive.The Cost Breakdown: What You’re Actually Paying For

The price of a generic pill comes down to four main parts:- Active Pharmaceutical Ingredient (API): This is the actual medicine. It’s often the biggest cost, and it can swing up or down 20-30% a year based on where the raw materials come from. If a chemical plant in China shuts down, prices jump.

- Excipients: These are the fillers, binders, and coatings. Think of them as the scaffolding that holds the medicine together. They’re cheap, but they add up in volume.

- Quality control: Every batch must meet FDA standards. Testing, documentation, audits - this isn’t optional. It’s built into the cost, but it’s far cheaper than running full clinical trials.

- Packaging: Bottles, labels, blister packs. Simple, standardized, and mass-produced.

Why Branded Drugs Still Cost So Much

Branded companies don’t just sell medicine. They sell a story. They pay doctors to prescribe. They run TV ads. They sponsor patient support groups. They even pay pharmacies to prefer their brand over generics - sometimes offering rebates that make the branded version cheaper for insurers than the generic. That’s why, even though 90% of U.S. prescriptions are filled with generics, they only make up 15.8% of total drug spending. The rest? Branded drugs. A single branded drug like Humira can cost $2,000 a month. A generic version of a common blood pressure pill? $4. The math doesn’t lie: patients are getting the same effect, but paying a fraction of the price.Where Generics Struggle

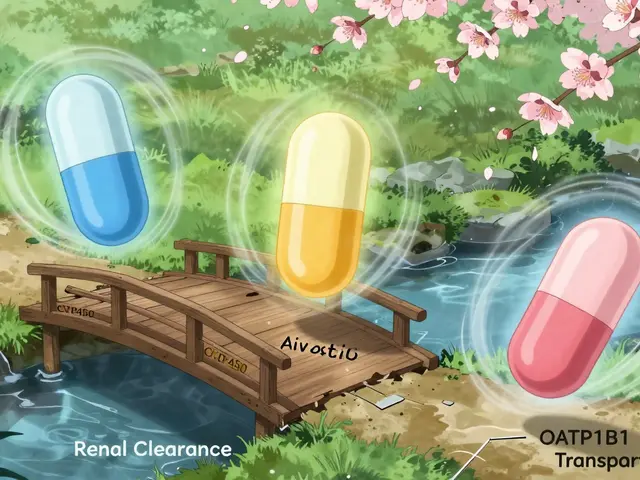

Not all drugs are easy to copy. Complex formulations like inhalers, injectables, or transdermal patches require advanced manufacturing. The equipment is expensive. The process is finicky. A single mistake can ruin a batch. That’s why there are fewer generic versions of these drugs - and why they cost more than simple pills. Even then, the price gap is still huge. A generic inhaler might cost $50 instead of $300. That’s still an 83% savings. The barrier isn’t cost - it’s technical complexity. But as technology improves, more complex generics are entering the market.Supply Chains Are Fragile

Here’s the dark side: because generic manufacturers operate on razor-thin margins, they can’t afford to keep extra inventory. When a raw material supplier has a problem - say, a factory fire in India or a shipping delay from China - there’s no backup. That’s why we saw over 350 drug shortages in 2022. Most were generic drugs. The system is designed for efficiency, not resilience. One company makes 80% of the API for a drug. If they go down, the whole supply chain stalls. And because no one wants to invest in excess capacity - it cuts into profits - the system stays vulnerable.

What’s Changing Now?

The FDA is trying to fix delays. Their new GDUFA III program, launched in 2023, is speeding up approval times from 40 months to 24. That means more generics hit the market faster - and prices drop quicker. The Inflation Reduction Act also lets Medicare negotiate drug prices. While it targets branded drugs first, it puts pressure on the whole system. If Medicare pays less for a branded drug, manufacturers have to lower prices - and that pushes generics down too. Automation is another game-changer. Companies are investing in continuous manufacturing - machines that run 24/7, making pills without stopping. This cuts costs by 20-25% by 2027, according to the Association for Accessible Medicines. But there’s a catch: if all generic production moves out of China, costs could rise 5-8% in the short term. That’s because new factories in the U.S. or India aren’t as efficient yet. But long-term, that’s a good thing - it reduces reliance on one country for the world’s medicine.Why This Matters for Everyone

From 2023 to 2027, generic drugs are projected to save the U.S. healthcare system $1.7 trillion. That’s not a guess. That’s a projection from IQVIA based on real pricing trends and prescription volumes. That money doesn’t just stay in insurance company pockets. It goes to patients who can afford their meds. It goes to hospitals that don’t have to cut services. It goes to taxpayers who fund Medicare and Medicaid. Generic drugs aren’t just cheaper. They’re essential. They keep people alive. They keep the system from collapsing under its own weight.What’s Next?

Biosimilars - generic versions of complex biologic drugs - are the next frontier. They’re harder to make than pills, but the same rules apply: scale, efficiency, and competition drive prices down. Early data shows biosimilar production costs fall 15% every time output doubles - just slightly slower than small-molecule generics. The future isn’t about more expensive drugs. It’s about smarter, faster, and more resilient ways to make the same life-saving medicines at a fraction of the cost.Are generic drugs as safe as brand-name drugs?

Yes. The FDA requires generic drugs to have the same active ingredient, strength, dosage form, and route of administration as the brand-name version. They must also prove bioequivalence - meaning they work the same way in the body. The only differences are in inactive ingredients, like fillers or color, which don’t affect safety or effectiveness.

Why do some generics cost more than others?

Price differences come down to competition. If only one company makes a generic, it can charge more. When five or more companies make it, prices drop dramatically. Supply chain issues, like API shortages, can also cause temporary spikes. Geographic location and pharmacy markup play roles too - but the drug itself is identical.

Do generics take longer to work?

No. Bioequivalence testing proves generics are absorbed into the bloodstream at the same rate and to the same extent as the brand-name version. Whether it’s ibuprofen, metformin, or sertraline, the effect starts and ends at the same time.

Why do pharmacies sometimes switch my generic?

Pharmacies often switch generics to the lowest-cost option available under your insurance plan. All approved generics are therapeutically equivalent, so switching doesn’t affect your treatment. If you notice a change in appearance, it’s just a different manufacturer - not a different drug.

Can I trust generics made overseas?

Yes. The FDA inspects all manufacturing facilities - whether in the U.S., India, China, or elsewhere - using the same standards. A 2023 FDA report found that over 95% of inspected generic drug plants met quality requirements. The location doesn’t determine safety - the inspection process does.

Will generic prices keep falling?

Yes - but only if competition stays high. More manufacturers entering the market = lower prices. Automation, continuous manufacturing, and regulatory reforms are pushing costs down further. However, if consolidation reduces the number of makers - as seen in some therapeutic areas - prices could stabilize or rise slightly. The trend, though, is still downward.

Shayne Smith

December 6, 2025 AT 22:16Just bought a bottle of generic ibuprofen last week for $1.50 at Walmart. My old brand-name ones used to cost me $18 at CVS. Same pill. Same effect. I didn’t even notice a difference. Why pay extra for a logo?

Also, my grandma takes generics for everything and she’s 82 and still hiking. So yeah, they work.

Max Manoles

December 8, 2025 AT 17:01The math here is irrefutable. The $2.6 billion R&D figure for branded drugs is inflated by corporate accounting practices - much of it is marketing, litigation, and shareholder dividends disguised as ‘innovation.’ Generic manufacturers don’t replicate the molecule; they replicate the *value proposition* - efficacy without the branding premium.

What’s rarely discussed is that the FDA’s bioequivalence threshold allows for a 20% variance in absorption. That’s not ‘same’ - it’s ‘close enough.’ For most people, fine. For those on narrow-therapeutic-index drugs? Riskier than we admit.

And yes, scale drives cost down - but only if you have the capital to build the factories. That’s why Teva and Sandoz dominate. It’s not free market. It’s oligopoly with cheaper labels.

Rashmi Gupta

December 9, 2025 AT 21:26You people act like generics are some miracle of capitalism. But what about the workers? The factories in India and China? They’re pumping out pills 16 hours a day for $3 a shift. The ‘low cost’ you’re celebrating? It’s built on exploited labor and environmental neglect.

And don’t get me started on how the FDA inspects plants - they send inspectors who fly in for a day, get shown the cleanest corner, and call it a day. Meanwhile, the real production lines are running with broken sensors and half-trained staff.

Generics aren’t cheaper because they’re smarter. They’re cheaper because someone’s getting crushed to make them.

Kumar Shubhranshu

December 11, 2025 AT 20:33My anxiety med switched from brand to generic and I felt like I was drowning

Same active ingredient but my body knew the difference

Now I pay extra because my life isn’t a spreadsheet

Karen Mitchell

December 13, 2025 AT 18:49It is deeply concerning that society has normalized the substitution of life-saving pharmaceuticals with economically optimized alternatives. The FDA’s bioequivalence standards are not equivalent to therapeutic equivalence. The notion that a pill with different excipients is ‘the same’ is a dangerous fallacy propagated by corporate interests.

One must ask: if the drug is truly identical, why does the brand-name version still exist? The answer is obvious - because the system is rigged to protect profit over patient safety.

And let us not forget: the supply chain fragility you so casually mention is not a bug - it is a feature of deregulated, profit-driven healthcare.

olive ashley

December 14, 2025 AT 21:05Ever wonder why every generic drug has the same weird shape and color? They’re all made in the same three factories in China and India. The FDA doesn’t inspect them - they get a photo and a PDF.

And those ‘cheap’ pills? They’re often the same ones that get recalled for contamination - but only after people start getting sick.

Meanwhile, Big Pharma is laughing all the way to the bank because they just sold you the same pill for $15, then sold the generic version for $2 - and got paid twice.

They own the patents, the supply chain, and now the FDA. You’re not saving money. You’re just being played.

Ibrahim Yakubu

December 16, 2025 AT 19:31Back home in Nigeria, we don’t even have access to real generics. What’s sold as ‘generic’ here? Half of it is fake or expired. The ones that work? Imported from India - but even those are often counterfeits with half the active ingredient.

You Americans think this is about cost. It’s not. It’s about control. The same companies that make the brand-name drugs own the generic ones. You’re not saving money - you’re being sold the same product under a different name.

And yes, I’ve seen the factories. They’re not clean. They’re not safe. They’re just cheaper.

So don’t tell me generics are ‘essential.’ They’re the cheapest way to keep people alive while the system steals from them.

Gwyneth Agnes

December 17, 2025 AT 16:09