Manufacturing Cost in Pharmaceuticals: What Drives Price and Quality

When you buy a pill, you’re not just paying for the chemical inside—you’re paying for how it was made. Manufacturing cost, the total expense of producing a medicine from raw ingredients to sealed bottle. Also known as drug production cost, it includes everything from sourcing active ingredients to cleaning machines between batches. This isn’t just a number on a balance sheet—it shapes whether a life-saving drug is affordable, available, or even made at all.

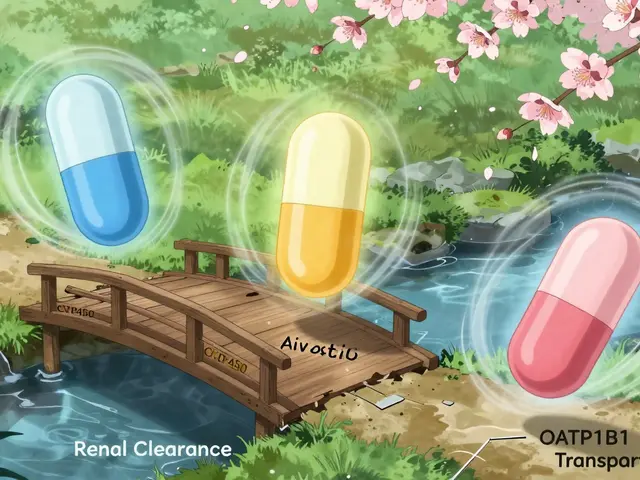

At the heart of pharmaceutical manufacturing, the complex process of turning chemicals into safe, consistent medications are two big drivers: scale and control. Making a generic version of a common drug like metformin in a high-volume facility in India or China can cost pennies per pill because production runs last for months, and automation keeps labor low. But if that same drug needs to be made in a sterile, FDA-approved facility with constant environmental monitoring to prevent contamination, the cost jumps. That’s why API manufacturing, the production of the active pharmaceutical ingredient, often the most expensive step—can account for up to 80% of total cost. Even small changes in how the API is purified or crystallized can affect stability, shelf life, and whether the final product passes regulatory tests.

It’s not just about money—it’s about risk. A cheaply made drug might save money upfront, but if it degrades too fast or has impurities, it can cause real harm. That’s why companies track things like humidity during packaging, microbial contamination in clean rooms, and even the temperature of water used to rinse equipment. These aren’t luxury checks—they’re legal requirements. And when recalls happen, like those tied to faulty manufacturing quality, the consistency and safety standards applied during drug production in certain overseas plants, the cost isn’t just financial—it’s measured in lost trust and patient safety.

What you’ll find in the posts below isn’t just theory. It’s real-world insight into how these costs play out: why switching generics can be risky, how Chinese factories supply most of the world’s drug ingredients, why shelf life testing matters more than you think, and how environmental monitoring isn’t just paperwork—it’s the line between a safe pill and a dangerous one. You’ll see how the same drug can cost $5 or $50 depending on who made it, where, and under what conditions. This isn’t about blaming manufacturers. It’s about understanding what’s really in your medicine—and why it costs what it does.

Manufacturing Cost Analysis: Why Generic Drugs Are So Much Cheaper

Generic drugs cost far less than brand-name versions because they skip expensive R&D, rely on economies of scale, and face fierce competition. Learn how manufacturing efficiency drives down prices without sacrificing safety or effectiveness.