FDA Recall Process: How Unsafe Medications Are Removed from the Market

When a drug turns out to be unsafe, the FDA recall process, the official system the U.S. Food and Drug Administration uses to remove harmful medications from circulation kicks into action. It’s not a single step—it’s a chain of checks, warnings, and actions designed to protect patients before harm spreads. The FDA doesn’t wait for mass casualties; it acts when evidence points to contamination, mislabeling, dangerous side effects, or manufacturing flaws. This process is how a batch of contaminated blood pressure pills or a diabetes drug with undeclared allergens gets pulled before it reaches your medicine cabinet.

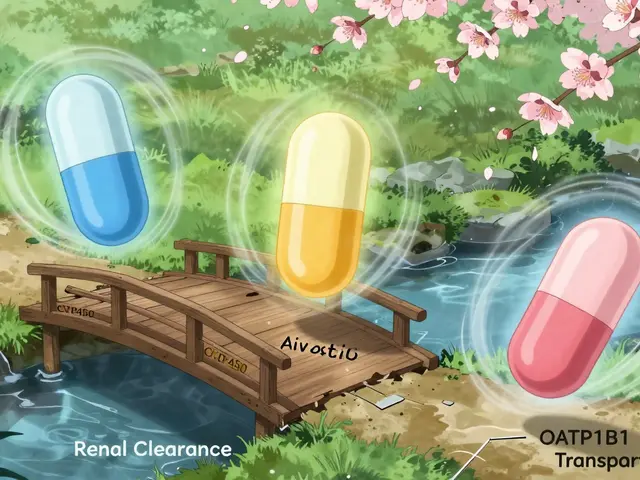

Behind every recall are pharmaceutical recalls, voluntary or mandatory actions taken by drugmakers or ordered by the FDA to remove unsafe products. These aren’t just about bad batches—they often reveal deeper issues like drug manufacturing quality, the standards and practices used to produce active ingredients and finished pills. For example, if a Chinese supplier’s API (active pharmaceutical ingredient) is found to contain carcinogens, the FDA can trigger a recall on every drug made with it—even if the final product was made in the U.S. That’s why recalls often ripple across brands and countries. The FDA also tracks medication safety, the ongoing monitoring of how drugs behave in real-world use after they’re approved, using reports from doctors, patients, and pharmacies to spot patterns that clinical trials missed.

Not all recalls are the same. Class I is the most serious—when using the drug could cause serious injury or death. Class II might lead to temporary health problems. Class III is the least urgent, usually involving labeling errors that won’t hurt you but still break the rules. The FDA doesn’t just announce recalls—it works with companies to notify pharmacies, hospitals, and the public. Sometimes, it’s a simple press release. Other times, it’s a targeted alert to providers who prescribed the drug. What you see online or in the news is just the tip of the iceberg. Behind it, there are lab tests, inspection reports, and internal reviews that took weeks or months to confirm.

What you won’t always hear is how often recalls are triggered by patient reports. Someone notices their pills look different. A pharmacist spots a wrong label. A family member finds a child got the wrong dose. These real-world clues are what keep the system working. The FDA doesn’t have eyes everywhere, but it listens to people who notice something’s off. That’s why your brown bag medication review or reporting a side effect isn’t just helpful—it’s part of the safety net.

What follows in this collection are real stories and deep dives into how drugs end up in recall lists, what went wrong, and how you can protect yourself. You’ll find posts on how generic drug manufacturing in China triggers recalls, how contaminated blood pressure meds were caught, and why some side effects like joint pain from DPP-4 inhibitors led to FDA warnings. You’ll also see how tools like smart pill dispensers and brown bag reviews help catch problems before they become emergencies. This isn’t theoretical—it’s about the systems that keep your medicine safe, and the people who make them work.

How to Verify Recall Notices and Affected Medication Lots

Learn how to verify drug recall notices and affected medication lots using FDA guidelines, step-by-step protocols, and real-world best practices to protect patients and avoid legal risks.